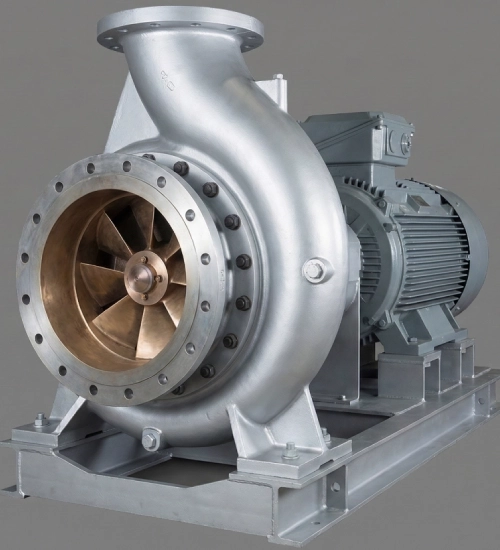

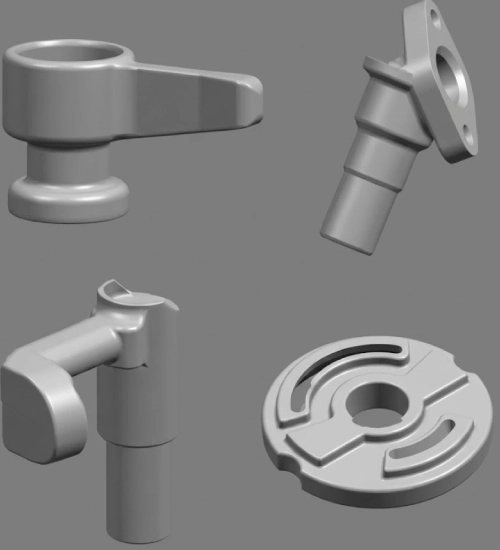

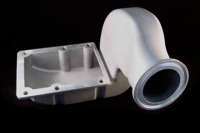

Vertex Investment Casting's proprietary processes allow us to cast very fine detail and intricate shapes in non ferrous materials when your project demands it.

We are one of the leading ferrous casting manufacturers offering wide range of ferrous casting components in domestic and international market as well.

Our long customer based included the Valve industries, pumps, Aerospace, Pharma industry, Automobiles, Defence & General Engineering.

We begin by creating precise wax patterns that are replicas of the final part. This is typically achieved by injecting wax into a metal die to ensure accuracy and consistency.

Each wax pattern undergoes a rigorous inspection to ensure it meets all quality and dimensional specifications. Only patterns that pass this strict quality control are approved for the next stage.

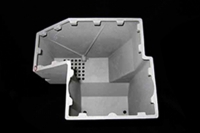

Multiple inspected patterns are carefully assembled onto a central wax sprue, creating a "tree." This allows for the efficient and simultaneous casting of multiple components.

We take pride in the trust our clients place in our casting solutions. Whether it’s precision, durability, or timely delivery — our team consistently delivers results that exceed expectations. Here’s what some of our partners have to say:

Vertex Casting exceeded my expectations. Their team is highly skilled, and the entire process was smooth from start to finish. The final output was exactly what we needed—high-quality, precise, and delivered on time.